ExtrudeX – 3D Printable Filament Recycler & Maker

- BackerBuzz

- Dec 5

- 2 min read

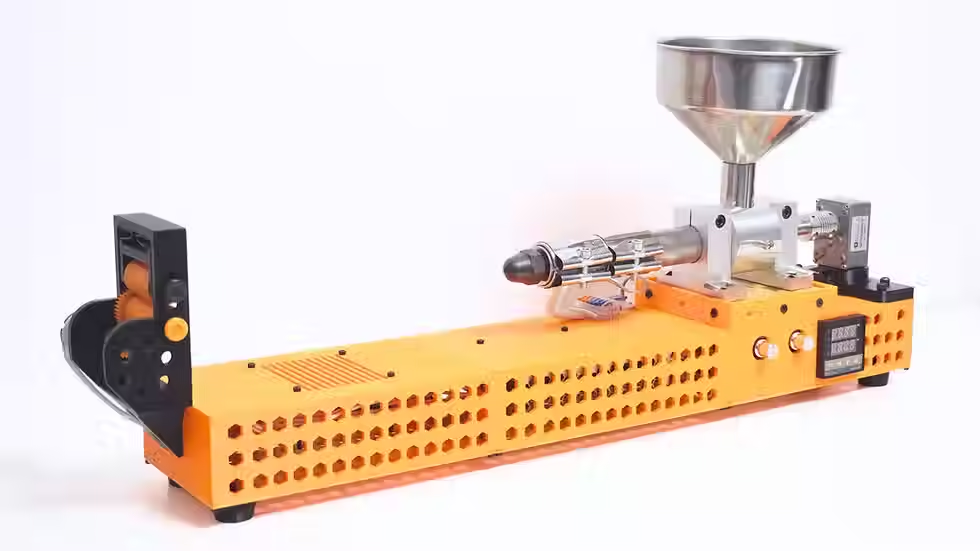

A compact, fully 3D printable machine that recycles failed prints and purge waste into new filament - easy, efficient, and sustainable.

Close the Loop: Turn Your Failed Prints into Fresh Filament with ExtrudeX

Every 3D printing enthusiast knows the pain of "filament poop"—the piles of support material, purge lines, and failed spaghetti prints that end up in the trash. Creative3DP is tackling this waste problem head-on with ExtrudeX, a fully 3D-printable machine that lets you recycle your scrap plastic into brand-new, usable filament right from your desktop.

Project Overview

Name and Creator: ExtrudeX – 3D Printable Filament Recycler & Maker by Creative3DP.

What It Is: ExtrudeX is a DIY filament extrusion system designed for home makers. Unlike expensive commercial recyclers that cost thousands of dollars, ExtrudeX is a machine you build yourself. It is a hardware-only design, meaning there is no complex coding, firmware, or programming required—just mechanical engineering that works.

Key Features

100% 3D Printable Design: You print the machine's body and structural parts yourself, keeping costs low and customization high.

Recycle at Home: Capable of processing common materials like PLA, PETG, and ABS. It is designed to work best with a mix of virgin pellets (60%) and shredded waste (40%), turning your scrap into functional 1.75mm filament.

No Firmware Needed: The system relies on pure hardware—motors, heaters, and PID controllers—eliminating the need for Arduino coding or software updates.

Compact & Accessible: It fits on a standard desktop and doesn't require an industrial shredder; simple home grinders (like a blender) can prepare the waste for the hopper.

Affordable Build: While you print the plastic parts, the bill of materials (BOM) for the non-printable components (motors, heaters, power supply) is estimated to cost between $150–$200 USD.

Rewards

Digital Files (STL): The core reward gives you the STL files and comprehensive assembly guide to print and build the ExtrudeX at home.

Hardware Kits: For those who don't want to source parts individually, Creative3DP plans to offer optional kits containing all the necessary non-printable hardware (motors, barrel, electronics).

Recycling Bundles: Higher tiers include files for PETFusion 2.0, a companion machine that turns waste plastic bottles into filament, allowing you to set up a complete home recycling station.

Concept

The concept behind ExtrudeX is "accessible sustainability." The team at Creative3DP realized that while many makers want to recycle, the barrier to entry has always been the high cost of equipment. By distributing the machine as digital files, they remove shipping costs and manufacturing overhead, empowering the community to solve their own waste problem using the very tools that created it.

Inspiration

The project was inspired by the sheer volume of plastic waste generated by the 3D printing hobby—specifically "poop" (purge waste) and support structures. Creative3DP wanted to create a solution that wasn't just for industrial labs but for the average garage tinkerer. Their philosophy, "Your prints should have purpose," drives the design, ensuring that even the waste from your projects can find new life as your next creation.